Matthew kicks things off by using a pre CCD (Charge Coupled Device) video camera from 1981 to symbolize the ”old/legacy’ ideas. He explained his setup using OBS (Open Broadcaster Software) and a virtual camera output to stream the combined videos of his studio into Zoom. His point was look how far we’ve some in 20 years! The same could be true in Industry 4.0. But legacy limits industries.

The Byzantine Maze of Industry 4.0

Matthew draws a close analogy between OT (Operations Technology) and Telecoms. Showing the similarity of the Strowger Switch and the Drum Sequencer. Electro-mechanical devices that began the automation of Telecoms and OT.

They even went through the same three phases of electromechanical to solid state to software (digital exchanges). On the industrial side it was the programmable logic controller (PLC). Two similar evolutions, but relatively unaware of each other’s existence.

This history lead to the same legacy thinking we see today across both industries.

I learned a new word, anemoia is a term used to describe the feeling of yearning for a time or place that one has never experienced. When I look back at my training as I joined BT, history was highly compromised, given the limitations of technology. And that technology became commoditized, in some industries, just not where there were large incumbent vendors that tried their best to limit that commoditization.

I’d been programming on a Commodore 64 and Atari ST 520 for years by this point. To a young naive me, it was just a software problem, connecting identities over a hierarchical infrastructure of packets or cells or slots or frames.

BUT this history had trapped the processes in the past. Resulting in the interfaces between data, devices, and people being high friction. Matthew shared the usual factory floor situation of a group of engineers huddled around a laptop on a table that is directly connected to the PLC.

I never saw a laptop connected to a System X, as there was a dedicated management layer and staff. Matthew highlighted that the data focus meant using the network to make the production line data available anywhere within the organization was made too complex to limit commoditization.

Gordian Knot of Transformation

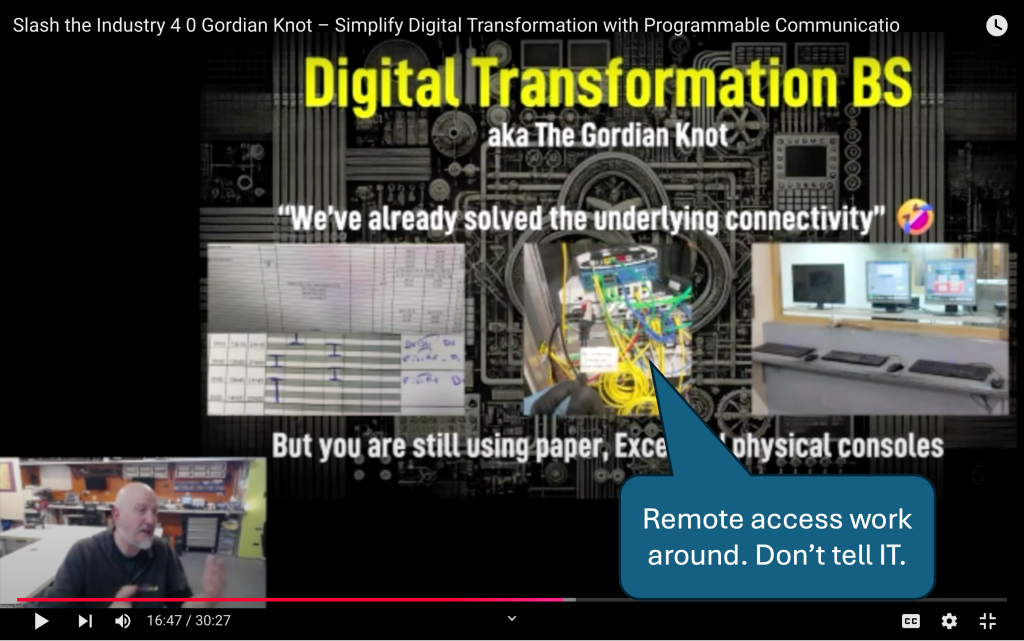

That friction led to paper, excel and physical consoles being used by default on the factory floor. There is also the IT / OT divide, so the OT LAN and IT LAN were separate. More a people issue fighting for budget within the organization.

Often there were secret ADSL boxes, routers, and firewalls to let contractors get remote access to the PLC. Matthew shows a great example from his experience of such a work around technology cluster.

Regardless of the grand OT design; people always find a way to solve an immediate problem, regardless of the security implications.

Matthew then moves onto something I’ve heard many times in telcos, that is dashboards and data lakes. The data needed to be normalized and contextualized. This is generally not done, so the dashboards do not deliver.

Vested Interests

Matthew does a great job highlighting the problems we face today in vested interests. Standards played an important role in the ’80s and ’90s. I worked on FSAN, Full Service Access Network Initiative, that lead to the deployment of FTTH around the world.

But more recently standards are used by the large incumbent vendors to limit competition. The RCS specification was overly complex, fortunately Google bought Jibe, so that barrier was removed. However, many telecom standards use tens of cross referenced documents, written in anything other than plain English. The objective is to limit comprehension to the few who worked on those standards.

Industry consortia, old-boys clubs, create overly complex checklists. Corporate procurement uses those checklists as a box ticking exercise. Asking for stuff they do not need, using overly complex processes. Rough consensus / running code would make far more sense for APIs in broad use today, rather than reinvention in the Camara standards by people not working at the coalface.

Corporate procurement make decisions that on the face of it seem financially best for the telco. But in practice are operationally poor, for example SMS firewalls where the overly impressive economics result in AIT (Artificially Inflated Traffic) being introduced to the telco’s network. That is, stealing money from the customers.

Also Industrial Automation and Telecoms remains isolated islands. Opportunities to integrate are limited. However, the IETF has a broad reach, standards like vCon can be used across industries. So it’s not an entirely closed door.

Escape The Labyrinth

What does it means to be sustainably digitally transformed? Transformation is a continuous process. Technology, competition, customer demand is constantly evolving. Transformation is continuous, remember the TQM (Total Quality Management) term, continuous improvement?

This leads to concepts that help enterprises continuously evolve like Unified Name Space, MQTT, vCon, etc. vCon makes the list as on the factory floor there are many conversations, and those conversations are lost. vCon enables the conversations to be remembered, and the chain of conversations that led to a decision on the production line is now transparent.

It’s great to see Telecoms, Operations Technology, and Information Technology finally working together thanks to IETF standards like vCon.

One thought on “Slash the Industry 4 0 Gordian Knot – Simplify Digital Transformation with Programmable Communication, Matthew Smith”

Comments are closed.